In many design studios and engineering departments, 3D rendering is still perceived as a final stage — the moment when the product is already defined and all that remains is to “make it look good.” However, in demanding professional environments, rendering is far more than an aesthetic resource. It becomes a tool for validation, communication, and decision-making. In that context, KeyShot occupies a distinctive position within the 3D visualization ecosystem.

Unlike other engines that prioritize real-time speed or extreme technical complexity, KeyShot has built its positioning on a specific balance: physical realism, workflow fluidity, and direct CAD integration. This makes it more than just a tool for attractive images; it becomes a key component in the product development process.

From Technical Model to Commercial Image Without Friction

One of the main challenges in industrial environments is the transition between engineering and marketing. CAD models are typically optimized for manufacturing, not visualization. Historically, this meant complex exports, material reconstruction, and time-consuming technical adjustments.

KeyShot addresses this with a clear philosophy: work directly with CAD data without disrupting the original workflow. Its integration with tools such as SolidWorks, Rhinoceros, or Fusion 360 allows teams to maintain model consistency while refining materials, lighting, and cameras. When the design evolves — as it inevitably does — updates do not require starting from scratch. This reduces time, but more importantly, reduces friction between teams.

In practice, this means engineering departments can validate aesthetic decisions in parallel with technical development, while commercial teams can access realistic visuals even before a physical prototype exists.

Physical Realism as a Validation Tool

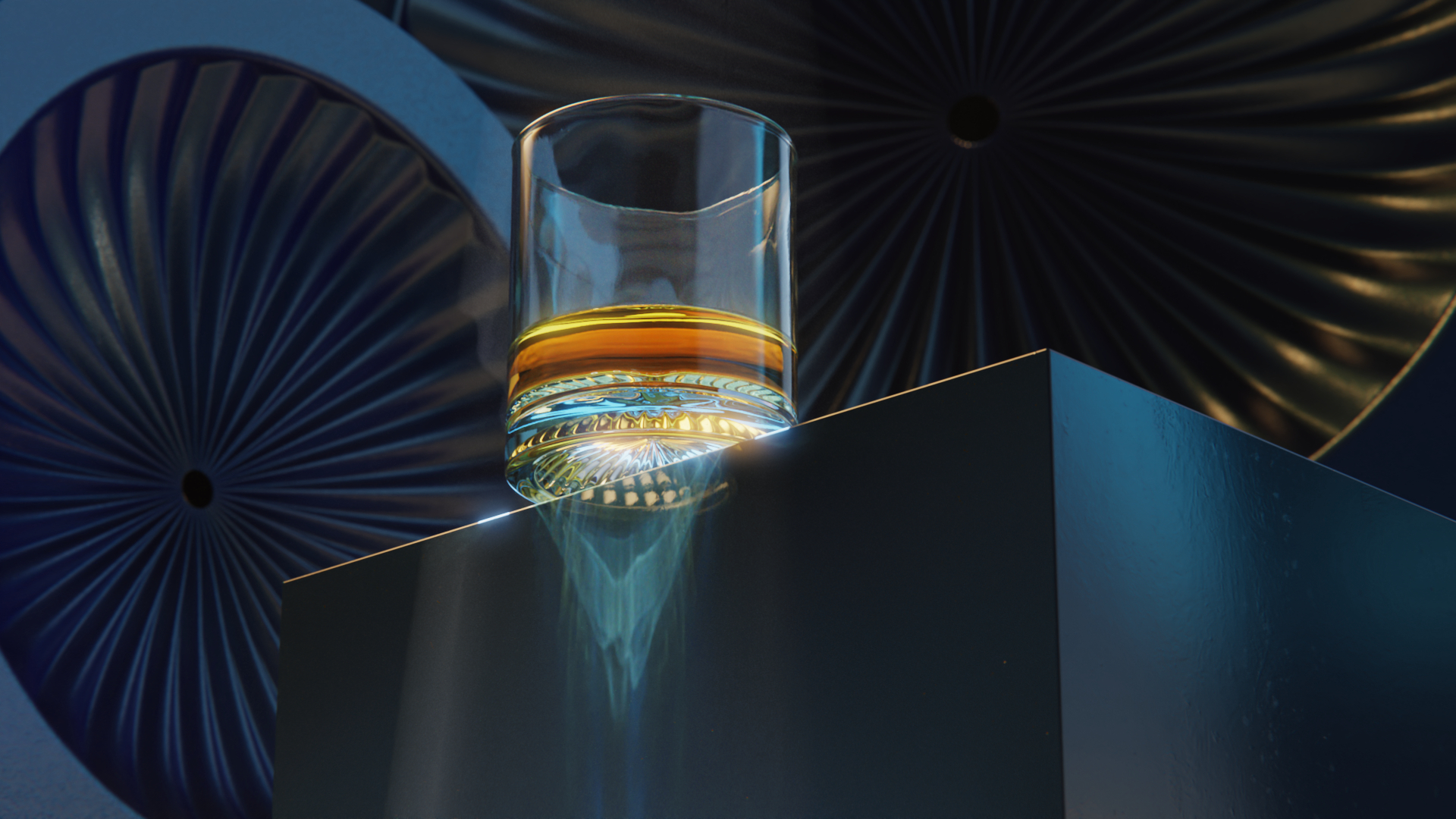

The value of a rendering engine in professional environments lies not only in image sharpness but in how accurately it represents materials and light. KeyShot is based on real-world physical properties. Reflection, refraction, roughness, and subsurface light scattering are not merely visual effects; they are simulations grounded in measurable parameters.

In sectors such as consumer electronics, automotive, or cosmetics, this precision is decisive. A metallic finish cannot simply “look like” metal — it must react like metal under different lighting conditions. A translucent plastic cannot be a flat texture; it must replicate how light penetrates and diffuses within it. These subtle differences directly influence product perception.

When a company uses rendering to validate materials before investing in molds or manufacturing runs, the image ceases to be decorative and becomes part of the strategic decision-making process.

Lighting and Context: Beyond the Isolated Object

Another key dimension is environment control. Many rendering engines require complex setups to achieve professional results. KeyShot simplifies global illumination management through highly controllable HDRI environments. This enables realistic simulations — from studio photography to showroom or outdoor settings — with a level of precision that directly impacts product storytelling.

It is not just about correct lighting, but about context. The same product can communicate technical robustness in an industrial setting or premium sophistication in a minimalist environment. Rendering is never neutral; it constructs brand narrative.

Technical Animation and Complex Communication

Beyond still imagery, KeyShot offers animation capabilities particularly valuable in technical industries. Assembly animations, exploded views, mechanical motion simulations, and camera sequences allow companies to explain complex processes without physical prototypes or live recordings.

In B2B environments, where sales cycles are often long and highly technical, these visual resources facilitate understanding and accelerate customer decision-making. Visualization becomes a bridge between engineering and business.

A Tool Aligned with Operational Efficiency

In increasingly competitive markets, speed-to-market is critical. Reducing prototyping time, improving internal communication, and generating commercial materials prior to manufacturing directly impact profitability. KeyShot aligns especially well with companies seeking a balance between visual quality and operational efficiency.

It is not solely targeted at digital artists or cinematic studios. It is designed for industrial designers, engineers, product architects, and technical marketing teams who need predictable, consistent results aligned with real business processes.

Conclusion

Referring to KeyShot merely as “rendering software” understates its potential. In professional environments, its true value lies in integrating visualization, validation, and communication within the full product development cycle. When rendering shifts from a final step to a strategic process component, the chosen tool makes a tangible difference.

In a context where imagery influences both technical and commercial decisions, a platform that combines physical accuracy, CAD integration, and usability is not a creative luxury — it is a competitive advantage.